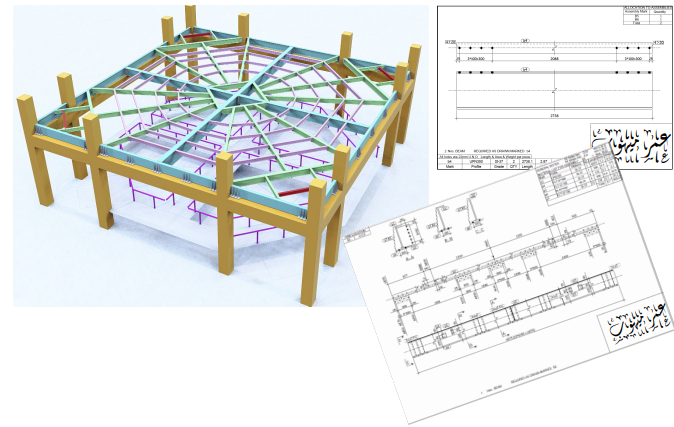

– Fully Detailed 3D Model (Intelligent 3D model helps steel fabricators work more efficiently. It helps at every stage of the process from design through fabrication and installation.)

– Single Part Drawings ( workshop drawings that show the fabrication information for one part [showing part‘s dimensions & holes diameter].

Single-part drawings usually use small sheet sizes, for example, A4 or imperial standard size 8.5″ x 11.5″.)

– Assembly Drawings (Typically workshop drawings showing fabrication information for one assembly. In most cases, an assembly consists of a main part and secondary parts. The secondary parts are either welded or bolted to a main part. Assembly drawings usually use larger sheet sizes than single-part drawings, for example, A3 or imperial standard size 11″ x 17″.)

– Genral Arrangement Drawings (GA drawings show the model from the most suitable direction. For example, in plan drawings, you are looking from the top of a building or floor down towards the ground. In elevation drawings you are looking from one of the sides of the building, like along a grid line. General arrangement drawings often contain enlarged views of complex areas or details, and other additional information that helps in the approval process and during the installation phase.)

– NC Files (NC [Numerical Control] refers to a method where machine tool operations are controlled with a computer. The NC data controls the motion of CNC (computer numerical control) machine tools. During the manufacturing process a machine tool or machining center drills, cuts, punches or shapes the piece of material.)

– All Needed Reports (Includes all project‘s data; like materials needed, part list, assembly part list & number of bolts needed for erection stage)

– Members Nesting (The nesting of groups enables the creation of hierarchical relationships that can be used to reduce member’s waste.)

– Members & Bolts Procurement Order (Preparing such documents makes workflow faster and no need for such process in the factory.)

– Manufacturing Follow-Up For Any Kind Of Technical Support (Our technical team is always ready to solve any issue at the fabrication or erection stages.)

Want to hire us?

Our Clients